Why Do Tie Down Straps Loosen?

If you are a long-distance transport driver and now you are driving on the highway with a truckload of cargo. Suddenly, you notice that the strap has loosened, and the cargo is shifting dangerously, causing the risk of falling down. What a terrible situation it is!

According to the AAA Foundation for Traffic Safety, over 25,000 crashes happen annually in the United States, due to improperly secured loads. Therefore, we must be seriously aware of the importance of ensuring that tie down straps remain secure during transit.

Understanding why tie down straps loosen is important for preventing accidents and ensuring the safety of your cargo and everyone on the road. Today, we will talk about the reasons why the tie down coming loose and the tips to prevent these issues.

Main Types of Tie Down Straps

When we talk about the types of tie down straps that are used on the market, the ratchet straps and cam buckle straps are the two most commonly used types. Other types of tie downs can be the extra protection of the cargo.

Ratchet Straps

Ratchet straps can be regarded as heavy duty tie downs. This device uses the ratchet mechanism to tighten and secure the loads, generally securing heavy loads, like machinery, vehicles, and large equipment, due to they can provide high tension and stability.

Common Issues Caused by Ratchet Straps

- Over-Tightening: The ratchet mechanism can easily cause over-tightening, which may damage the cargo and straps.

- Mechanism Jamming: The ratchet mechanism will get jammed if any dirt, debris, or rust. Under this situation, the ratchet mechanism is easy to release or tighten the strap.

- Wear and Tear: If use the ratchet frequently, the moving part will wear over time, this will reduce the mechanism’s reliability.

Cam Buckle Straps

Cam buckle straps are used to secure light weight cargo, such as furniture, bike, and recreational equipment. Using the cam mechanism, you will never worry about the over-tightening issue.

Common Issue Caused by Cam Buckle Straps

- Slippage: The cam mechanism relies on friction to hold the strap in place. If using the cam mechanism to hold heavy loads or the road is very bumpy during transportation, the mechanism may slip.

- Difficulty in Achieving High Tension: The cam mechanism is designed for light cargo securement. If you use it to secure heavy duty cargo, it is very hard to ensure safe securement.

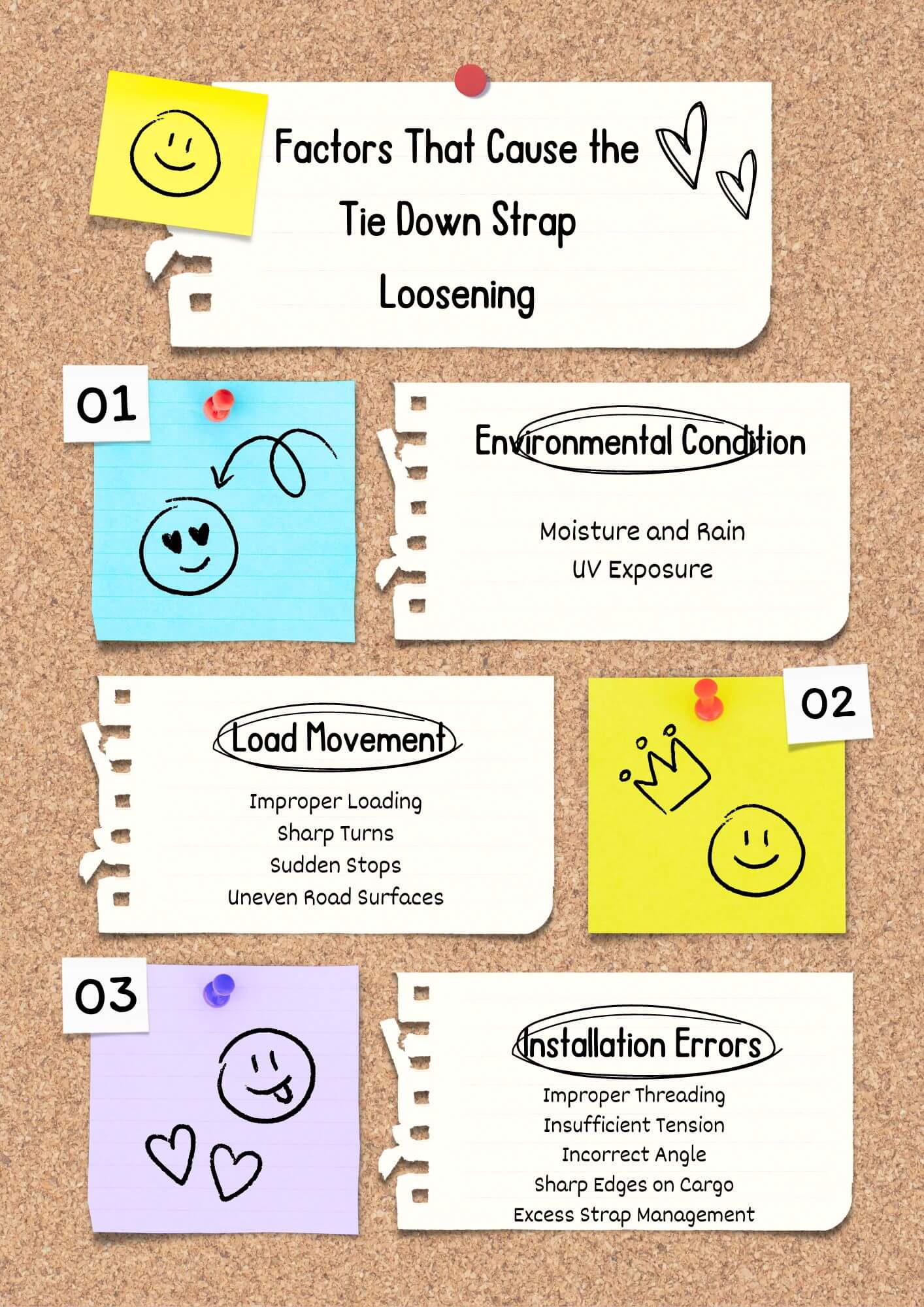

Factors That Cause the Tie Down Strap Loosening

Learn what factors may cause your tie down strap to come loose, you will pay more attention before your transportation.

Environmental Conditions

- Moisture and Rain: Exposure to moisture can weaken the fibers of the straps, cause mold and mildew growth, and then compromise their strength.

- UV Exposure: UV rays can degrade the material over time, and then cause the material to become brittle and lose its tensile strength.

Load Movement

- Improper Loading: When cargo is not evenly distributed, it is easy to shift during transportation.

- Sharp Turns: Sharp turns at high speeds can cause the load to shift sideways, under this condition, the strap may loose.

- Sudden Stops: Abrupt braking can cause the cargo to lurch forward, creating slack in the straps as the load shifts.

- Uneven Road Surfaces: Bumpy or uneven road conditions can jostle the cargo, causing it to move and the straps to lose tension.

Installation Errors

- Improper Threading: Not threading the strap correctly through the cam buckle or ratchet can prevent it from holding tension.

- Insufficient Tension: Before transporting, the worker does not tighten the strap enough will cause the strap loose.

- Incorrect Angle: Securing the straps at improper angles will reduce their effectiveness and increase the risk of loosening.

- Sharp Edges on Cargo: The sharp edge of the cargo can abrade or cut the straps, eventually the strap becomes damaged and loose.

- Excess Strap Management: Not securing the excess strap after tightening can lead to flapping in the wind, and then lead to gradually loosen.

Tips to Prevent Tie Down Straps from Loosening

The main reason that caused the tie down strap to get loose is like above. Now we’re going to turn the steering wheel to how to fix these issues.

About the Moisture and Rain Issues

- Use Waterproof Covers: Protect your cargo and straps with waterproof covers to prevent them exposure to moisture.

- Choose Water-Resistant Straps: Invest in straps made from water-resistant materials, such as polyester, which are less likely to absorb moisture and degrade.

- Dry Straps Thoroughly: If the tie down strap has already been exposed to rain, you need to dry the straps thoroughly before storage to prevent mold and mildew growth.

About UV Exposure Issue

- UV-Resistant Straps: Use straps specifically designed to resist UV degradation.

- Shade and Cover: Use the cover to keep your straps and cargo shaded to minimize direct UV exposure.

- Regular Inspection: Frequently inspect straps for signs of UV damage and replace any that show signs of brittleness or discoloration.

About Improper Loading Issue

- Balanced Loading: Ensure the load is evenly distributed and centered on the trailer to minimize movement during transit.

- Use Load Bars and Nets: Use load bars, cargo nets, or other securing devices to keep the cargo in place.

About Sharp Turns Issue

- Drive Carefully: Avoid sharp turns and high-speed maneuvers to prevent cargo from shifting.

- Securely Fasten Loads: Double-check and make sure all loads are securely fastened to withstand lateral forces.

About Sudden Stops Issue

- Gradual Braking: Apply brakes gradually to reduce the likelihood of cargo lurching forward.

- Extra Securement: Use extra straps or securing devices to hold the cargo in place.

About Uneven Road Surfaces Issue

- Plan Routes: Choose routes with well-maintained roads to minimize jostling.

- Additional Padding: Use padding or anti-slip mats to cushion the cargo and prevent movement on rough roads.

About Improper Threading Issue:

- Follow Instructions: Follow the manufacturer’s instructions to thread straps through buckles or ratchets.

- Double-Check Threading: Double check each strap is threaded correctly before tightening.

About Insufficient Tension Issue

- Achieve Proper Tightness: Ensure straps are tight enough to secure the load but not so tight as to damage the cargo.

- Use Ratchets: For high-tension needs, use ratchet straps that allow for more precise tension adjustments.

About the Incorrect Angle Issue

- Secure at Correct Angles: Ensure straps are secured at appropriate angles to maximize their working capacity and reduce the risk of loosening.

About Sharp Edges on Cargo Issue

- Use Edge Protectors: Put edge protectors or padding over sharp edges to prevent them from cutting into the straps.

About Excess Strap Management Issue

- Secure Excess Strap: Secure any excess strap length by tying it off or using strap keepers to prevent it from flapping in the wind.

Pre-trip and In-Transit Inspections

- Visual Inspection: Before starting the transportation, check for any visible wear and tear, fraying, or cuts on the straps.

- Tension Check: Ensure all straps are properly tightened and secure before departure.

- Periodic Re-Tightening: Stop periodically during transit to check and re-tighten straps as needed.

Choosing the Right Tie Down Strap

Before checking if any defects on the straps, you must meet the following two conditions.

- Appropriate Load Capacity: Ensure the straps you use are rated for the load you are securing. Never exceed the working load limit of the strap.

- Correct Strap Type: Choose the proper tie down strap type according to cargo type.

Before each transportation, we hope you will carefully check your cargo, your tie downs, and your transport vehicle. At any time, safe travel is the most important thing.

You may also interested in:

Your guide to the best tie down straps

Dave Lee

Dave Lee has amassed over two decades of experience in the cargo control industry, serving as a product manager. Prior to joining Webslingness, he spent three years at a transportation company.